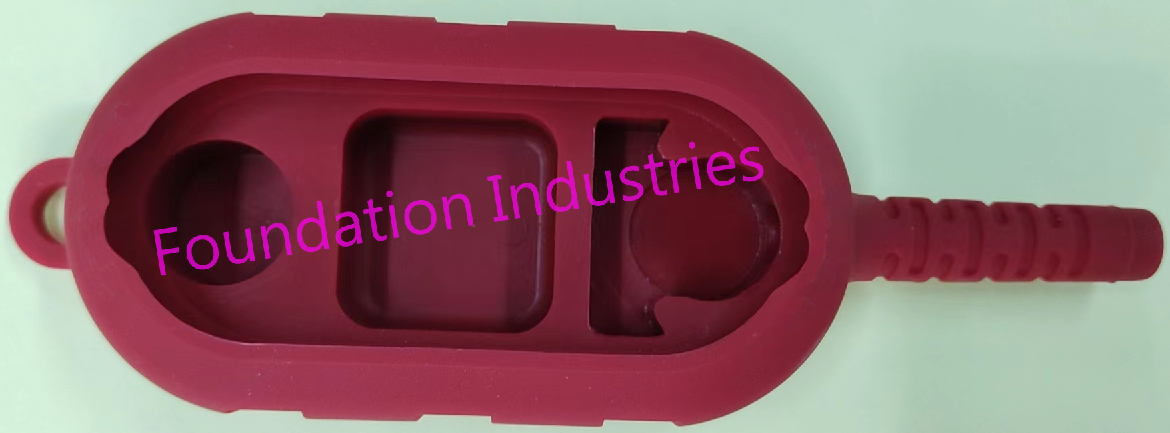

Icala lerabha lisigqubuthelo esikhuselayo esenziwe ngezinto ze-silicone ezisoloko zisetyenziselwa ukukhusela i-electronics, izixhobo, okanye ezinye izinto kumonakalo wangaphandle, i-abrasion, okanye i-vibration.I-Silicone yinto eguquguqukayo kunye nethambileyo ekwazi ukumelana nokuguga, amaqondo obushushu aphezulu naphantsi, iikhemikhali, kunye nokugqunywa kombane.Oku kwenza i-silicone ibe yinto efanelekileyo yokusetyenziswa kwimikhono ekhuselayo enika ukhuseleko olusebenzayo.

Imikhono ekhuselayo yesilicone inezi mpawu zilandelayo:

1. I-Anti-shock kunye ne-anti-impact: I-Silicone ine-softness elungileyo kunye ne-elasticity, eyenza ukuba ikwazi ukufunxa ukothuka kwangaphandle kunye nokungcangcazela, ngaloo ndlela inciphisa umonakalo kwizinto.

2. I-Anti-slip kunye ne-anti-fall: I-Silicone ibonisa inqanaba elithile le-viscosity, iphucula ukubamba izinto kunye nokuthintela ukuba baphume ezandleni kunye nokugcina umonakalo.

3. Ukungangeni kwamanzi kunye nothuli: I-Silicone ibonisa ukuchasana okugqwesileyo kumanzi kunye nothuli, ukuthintela ngokufanelekileyo ukungena kwabo kunye nokukhusela izinto emonakalweni kunye nokungcola.

4. I-Anti-scratch: I-Silicone iqhayisa ukuxhathisa okuphezulu kwe-abrasion, inika inqanaba elithile lokukhusela kwimikrwelo kunye ne-scuffs.

Ukusetyenzwa kokhuselo lwerabha olukhuselayo kubandakanya la manyathelo alandelayo:

1. Ukulungiswa kwezinto eziluhlaza: Lungisa izinto ezifunekayo ze-silicone, ngokuqhelekileyo i-silicone engamanzi, kunye nezinye izinto eziyimfuneko ezincedisayo.

2. Uyilo lokungunda kunye nolwakhiwo: Yila kwaye wenze ukubumba okuhambelanayo ngokusekelwe kwimilo kunye nobukhulu bemveliso.Iimolds zinokuba yi-silicone injection molds okanye i-compression molds, phakathi kwabanye.

3. Ukulungiswa kwejeli ye-silica: Hlanganisa ijeli ye-silica ye-liquid kunye ne-silica gel catalyst kwi-ratio efunekayo ukukhuthaza ukuphendulwa kokunyanga kwe-silica gel.

4. Isitofu okanye ukucinezela: Beka i-gel ye-silica edibeneyo kwi-mold eyenziwe ngaphambili.Ngenaliti ye-silicone, umatshini wokutofa ungasetyenziselwa ukujova i-silicone kwi-mold.Ukubumba i-press, uxinzelelo lunokusetyenziswa ukufaka i-silicone kwi-mold.

5. I-Flattening kunye ne-de-aerating: I-Flatten kunye ne-de-aerate i-gel ye-silicone emva kwesitofu okanye ucinezele ukuqinisekisa ukusabalalisa ngokulinganayo ngaphakathi kwi-mold kunye nokususa ama-bubbles emoyeni.

6. Ukunyanga kunye nokuqina: Abakhuseli be-silicone kufuneka baphiliswe kwaye baqiniswe phantsi kweemeko ezifanelekileyo zokushisa kunye nexesha.Oku kunokufezekiswa ngokunyangwa kwendalo, ukunyangwa kwe-oveni, okanye ukunyangwa okukhawulezileyo.

7. Ukuchithwa kunye nokugqiba: Emva kokuba i-silicone iphiliswe ngokupheleleyo kwaye ilukhuni, i-sleeve yokukhusela ikhutshwe kwi-mold, kunye nokugqiba okufunekayo, ukuchithwa kunye nokucoca kwenziwa.

8. Ukulawulwa komgangatho kunye nokupakishwa: Umkhono okhuselayo we-silicone uhlola umgangatho wokuqinisekisa ukuba uhlangabezana neemfuno eziqhelekileyo.Ukupakishwa ke kuqhutyelwa ukuthuthwa kwemveliso kunye nokuthengiswa.La manyathelo anokulungelelaniswa kwaye aphuculwe ngokusekwe kwiprosesa ethile kunye neemfuno zemveliso.

Kubalulekile ukuba uqaphele ukuba inkqubo yokucutshungulwa kwe-silicone kufuneka ihambelane nemimiselo efanelekileyo yokhuseleko ukuqinisekisa ukhuseleko lwabaqhubi kunye neemveliso.

Uyilo lwemikhono ye-silicone ngokuqhelekileyo lulungelelanise ukumila kunye nobukhulu bento ekhuselweyo, iqinisekisa ukufaneleka kunye nokukhusela okusebenzayo.Iimeko zeSilicone zisetyenziswa kakhulu kwizicelo ezahlukeneyo, kubandakanya iifowuni eziphathwayo, iitafile, abalawuli, izixhobo, kunye nokunye, ukunika ukhuseleko olongezelelweyo kunye namava omsebenzisi afanelekileyo.

Ixesha lokuposa: Nov-24-2023